Jens “jenslabs” Clarholm is an artist who leverages technology, notably a sophisticated drawing machine, as a central instrument for his exploratory and generative artistic endeavors.

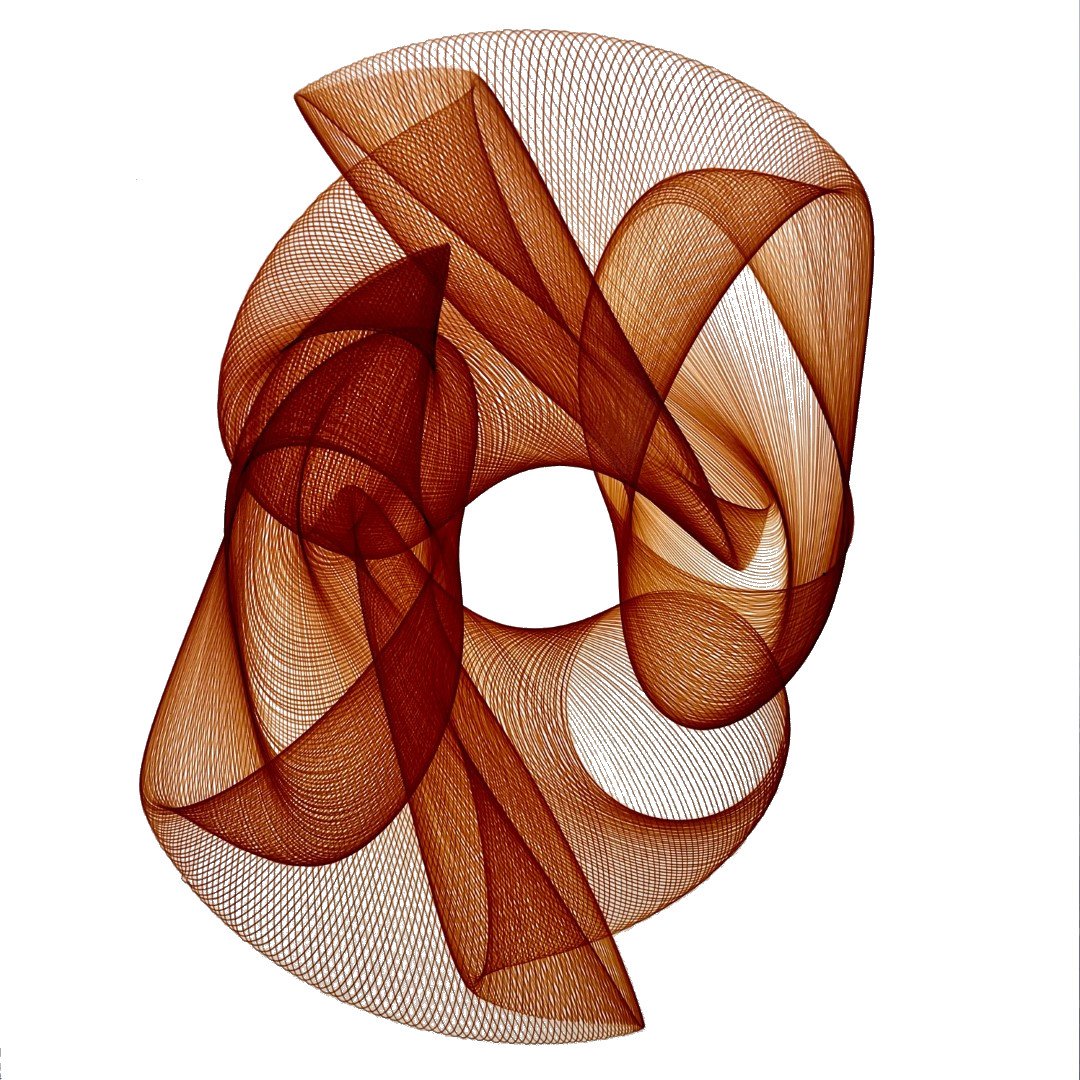

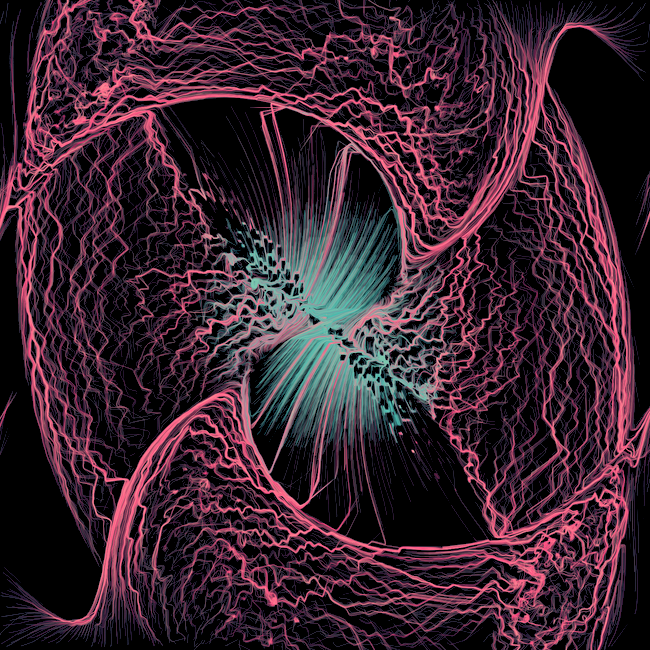

Drawing Machine Art - Analog generative art

I create my drawings using a drawing machine that I designed and built myself. Unlike a typical xy-plotter, this machine's output depends on the intricate interplay between the speed of three different motors and the connections between them. Most speed combinations result in random squiggles, but when I find the right harmonics, intricate patterns emerge. Operating the drawing machine feels more like playing a musical instrument than using a machine. It's akin to how a painter wields a paintbrush, and I often interact with the machine as it runs. I also craft my own tools, such as customized pen holders and ink dispensers, to further explore the synergy between man and machine.